This Article originally appeared on markforged.com and was written by Charlotte Weiss

______________________________________________________________

What are soft jaws?

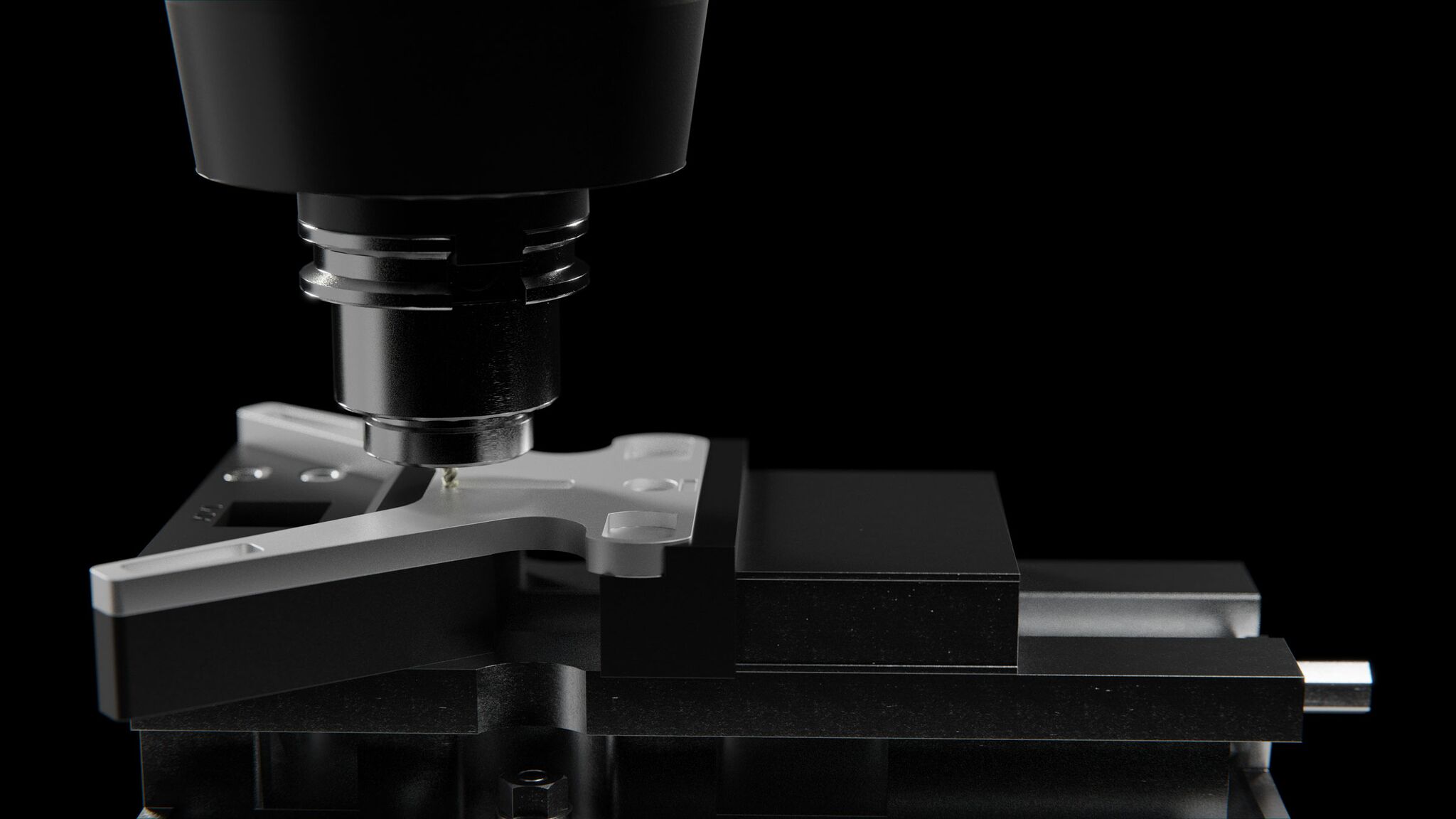

Soft jaws are a common solution for holding parts that would be difficult to fixture with standard, flat vice jaws during machining. Often milled out of aluminium or steel, soft jaws can also be 3D printed with the help of continuous fibre reinforcement.

Why 3D print soft jaws?

Fabricating soft jaws takes time and labour. Engineers and machinists have to first CAD the design and then take the design to program for machining on their CNC using CAM software. This is one of the most time-consuming steps in creating soft jaws. They then can finally fabricate the soft jaws and they may have to make small modifications. All of this adds up and takes precious time away from creating parts that generate revenue for your business. 3D printing doesn’t require you or anyone to do anything while the part is printing, which is a stark difference to the amount of hands-on work required for traditional manufacturing. By printing soft jaws, your team can focus on more pressing tasks that take up less time, while your other machines will be open for other operations.

Qualified and skilled machining labor is difficult to find. Industries are always looking for ways to utilize their talent. The time it takes to prepare a CNC for workholding could be better used in other areas of the manufacturing process, and 3D printers give companies the capacity to use their time wisely and with purpose.

You can watch our video on creating soft jaws below.

Request a free sample part from Markforged to test the strength of our material.