This article originally appeared on markforged.com

3D printing, also known as additive manufacturing, is used to describe one of many processes available that involve the conversion of a digital file into a solid, three-dimensional object. A 3D printer will repeatedly lay down or fuse successive layers of material together, tracing the file’s cross-sectional shape until a physical object takes form.

Fused Deposition Modeling (FDM) and Stereolithography (SLA) are the go-to 3D printing methods for professionals and hobbyists alike, offering considerable design flexibility for prototyping, general part fabrication and short-run manufacturing. Both are capable of producing similar part results, but details will always matter when choosing the best 3D process and material for the job.

In FDM, melted thermoplastic is extruded onto a build platform, fusing layer on top of layer, until a 3D shape takes form. FDM filaments range from biodegradable PLA plastic to tough, impact-resistant Kevlar reinforcement, making it extremely versatile for everything from prototypes to industrial tools and fixtures. FDM 3D printers are also customizable, allowing you a greater choice of print settings and hardware add-ons to accommodate a growing number of materials. With SLA, a UV laser or light projector successively traces each sliced layer of the object, curing photosensitive resin layers into a hardened plastic until a 3D shape takes form.

FDM

Advantages

There are an array of FDM thermoplastics and filament types to serve virtually any industry or application need. FDM 3D printers feature larger build volumes than SLA printers, enabling them to perform certain short-run manufacturing tasks in addition to prototyping full size, ready-to-use parts and models.

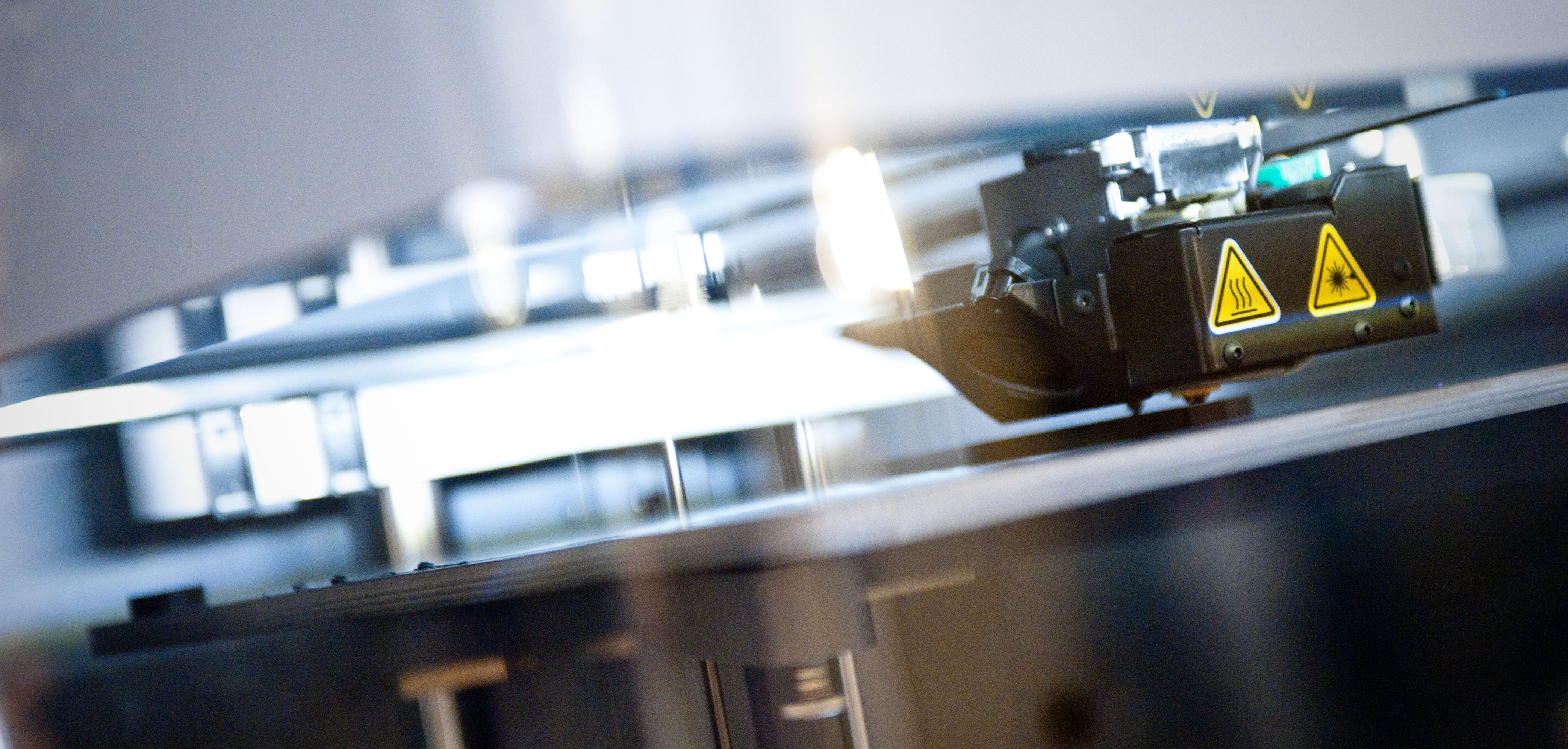

Traditional filaments continue to evolve with integrated features such as acid and chemical resistance, low friction, and high strength. Newer FDM filaments contain chopped fibre blends such as polycarbonate and carbon fibre to produce strong, lightweight, and dimensionally stable parts. FDM 3D prints can range from small replacement parts for classic cars to tools and fixtures for aerospace companies, making it the stronger choice for objects that require mechanical function and performance. Some FDM printers, such as Markforged’s industrial series X7 printer, have the ability to print at a 50-micron layer height, which overcomes typical FDM behaviours and produces parts with minimal or no visible layers and a smooth, even finish.

Using Markforged’s desktop or industrial series printers, configuration elements like selecting the right material, settings, and hardware are already in place, meaning that no user configuration is needed to combat delamination, the correct print speed, and incorrect filament deposition. While ensuring the part is a good candidate for print is still part of the process, adjusting temperatures or speeds isn’t needed to ensure a successful print.

Disadvantages

In general, due to FDM’s lower print resolutions, surface “layer lines” from the process sometimes show — even at fine detail settings. Also known as “ribbing”, additional polishing and sanding are required to even be comparable to the smooth surfaces of an SLA print. If you’re producing high-strength prototypes without an emphasis on surface detail, then it won’t matter.

Typically, FDM 3D printing process is also prone to temperature fluctuations, causing thermoplastic filament material to cool slower/faster and cause surface delamination (layer separation, warping). The FDM process entails a fair number of moving parts, all tasked working together to shape the object. Any issue with the printhead, extrusion system or hot end assembly will ultimately lead to issues mid-print. Therefore, careful attention to print settings, hardware, and material specifications is necessary when preparing and slicing your 3D model.

SLA

Advantages

SLA 3D prints can achieve resolutions as small as 25 microns, resulting in smooth, detailed surface finishes that are unrivalled by FDM and resemble injection moulded parts. It is best suited for presentation or “proof of work” concept models, organic structures, parts with complex geometries, figurines, and other unique form prototypes.

Thanks to the UV laser’s incredibly accurate curing process, SLA 3D prints offer tighter dimensional tolerances. This is because there is no thermal expansion during the fusion of layers, making it ideal for extremely accurate prototypes such as jewellery posts, medical implants, intricate architectural models, and other small components.

Disadvantages

Due to the cured resin material’s brittle characteristics, only engineering-grade SLA resin formulations should be used for parts that undergo mechanical stress or cyclical loads. Otherwise, most standard resins are ideal for delicate, detailed structures used for presentation purposes, such as cosmetic prototypes. There is no SLA resin on the market today comparable in strength and mechanical performance to filaments such as polycarbonate, nylon, or other tough FDM materials.

SLA 3D printing resins typically cost more and yield fewer parts per unit of resin than FDM 3D printing filament spools. They have considerably smaller build volumes when compared to FDM 3D printers and are not suited for volume jobs.

FDM or SLA?

The first step is to always decide on the best tool for the job. FDM and SLA both have their benefits and can be used to serve completely different tasks or in conjunction with multi-part assembly builds. If you’re looking to create fine feature design prototypes, then SLA is the better option. Otherwise, FDM will be more versatile for parts across the production process, from designing, to manufacturing, to maintenance.