Laser Scanning Services Perth

Todays 3D measuring solution

Terrestrial Scanning

Long range scanningTerrestrial scanning is typically used for large equipment as it can scan to from 120m to 300m with accuracy down to 2mm. The scan file is typically a cloud file.

Metrology Scanning

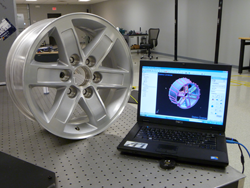

High accuracy scanningMetrology scanning is typically used for small equipment with the laser scanner is attached to a tripod. Metrology Scanning has around a 3M reach, and accuracy of 200 microns. The scan file is typically a mesh file.

Reverse Engineering

Creating real world modelsWith state of the art equipment we can measure and scan any object to recreate a 3D model for the purpose of replication, modification or fabrication.

Point Cloud Conversion

Turning scan data into useful modelsHave a point cloud would be usless to many clients if they don't have the correct software and hardware to turn that information into usable data. SFDesign can not only do the scanning but we can also turn that scan data into useful 3D geometry.